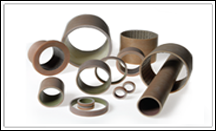

» DFG Range

The self-lubricating feature of the DUROFIT - DFG bearing is achieved by adding solid lubricants and functional fibers into the body material and the friction coefficient is decreased by the solid lubricate grease immersion. The friction coefficient is affected by the load, operating speed and shaft roughness. The friction coefficient is generally decreased along the load increasing and Increased along the operating speed.

The self-lubricating feature of the DUROFIT - DFG bearing is achieved by adding solid lubricants and functional fibers into the body material and the friction coefficient is decreased by the solid lubricate grease immersion. The friction coefficient is affected by the load, operating speed and shaft roughness. The friction coefficient is generally decreased along the load increasing and Increased along the operating speed.

» Advantages Polyglyd bearings vs Metal polymer bearings

Because the grease immersed in the solid plastic material, the lubricating will be valid continuously no matter how long the bearings are working. Comparing to the traditional metal composite bearing that the lubricating layer is around 0.03mm thick whose service life will be terminated whenever the lubricating layer peer off or wear off, the plastic bearing is a better option for longer lubricating service.

Slightly wear off will occur as soon as the self-lubricating bearing is applied with a certain load. It is the same to the DUROFIT – DFG series bearings, when the slightly wear occurs, the immersed oil (grease) will infiltrate out from the bearing filling the wear off area of the bearing as well as the mating material to form the lubricating film and therefore interrupt the wear process.

» Maximum surface static load :

The actual dynamic load is usually less than the maximum surface static load recommended in the data sheet. Due to the clearance exists between the shaft and bearings, the actual working surface area are not the same as the projected area of the bearing. The working area is depended on the clearance between the shaft and the bearing. The value in the datasheet is valid when the shaft is not moving or the operating speed is less than 0.01m/s. The value could also be applicable for a short run (shorter than 3 minutes) condition.

» The load, temperature and speed relatively

The load capacity will be decreased along with the temperature increase. Load capacity may sharply decrease when the operating temperature is higher than the recommended maximum temperature. The load capacity will be decreased along with the speed increase. Speed increase will result into a temperature increase that decreases the load capacity.

The operating speed is one of the key parameters for the sliding bearings. The friction between the sliding bearing and the shaft is a linear friction. So the operating speed of sliding bearing is much less than that of a rolling bearing where the friction is a rotation method. The speed here is the relative linear speed between the bearing and the shaft but not a rotation speed.

There is a limited temperature range that DUROFIT – DFG Series bearings could be used. The lowest temperature is the one the material will become brittle under that value and the highest temperature is the one the bearing material wear resistance feature will start to change. If the bearings are used under the conditions of alternatively changing high and low temperature, the bearing feature will be considerably affected and thus shorten the bearing service life.

» PV Value of Bearings

PV is the product of the specific bearing load P and the sliding speed V. It is a very important design data for the bearing application. The PV value is inverse proportional to the bearing service life ( . So it is recommended to consider a lower design PV value during the bearing selection.

» The Bearing Wear

As the bearings wear resistance affected by many factors, it is difficult to accurately describe bearing wear and life span.

Through numerous experiments we can conclude that the main factors affect the anti-wear property are the load, moving method, speed, roughness of mating surfaces, ambient temperature and dust and type of the outside lubricating medium, etc.

When the load, speed and temperature increase, the wear resistance of bearings gradually reduced; when there is outside lubrication medium, the wear resistance could be doubled; DUROFIT recommend the roughness of axis to be Ra0.4 ~ Ra1. 6. If the shaft is too rough or too smooth, it might increase the wear. Although there is no special restriction on the using of shaft .Material for the DUROFIT DFG series bearings, DUROFIT recommend the use of hard chrome plated shaft material. The recommended shaft hardness is over HRC 35 in order to avoid the initial wear off on the shaft.

» Bearing Installation Housing

The bearing housing and the fitting tools must be kept clean during the assembling. A chamfer of 25 on the housing should be ensured for an easy assembling. A stepped press pin is recommended to be used for the assembling. The inner diameter of the DUROFIT-DFG series product is measured after the bushing is fitted into the H7 housing.

» Shaft

There is no critical requirement for the shaft material but chrome plated shaft is recommended for better operation. Rounded chamfer is required on the shaft for easy assembling. DUROFIT recommend the shaft roughness to be in the range of Ra0.4~1.6. Please refer to Illustration 15 for the relation between the surface roughness and bearing friction coefficient. DUROFIT-DFG series products are designed according to ISO 3547 Standard. Although the DUROFIT-DFG bearings are designed for self-lubricating purpose, but the initial lubricating helps the assembling and the future operation of the bearings.

» Adhesive agent

DUROFIT-DFG series plastic bearing assembly generally needn't use glue, in case the glue is necessary, please consider the used glue can also work properly at the required temperature. Relative testing is recommended in this case.